QYT CB-58 is voluntary distributed in Japan by "CRKits Japan" as named "QYT-28" after modified 10m band for Ham Radio use. I got 1st prototype QYT-28 last year and also have chances to repair some of them until now. I would like to share my experiences how to repair them.

※Any repairs or modifications you make are your responsibility.

1. Replace of final FET (FQP13N10)

Unfortunately QYT CB-58 final FET(FQP13N10) is not fixed by screw, this is causing lack of heat dissipation. It is fitting to aluminium case via the white plate (looks like ceramic plate ?) without fixing by screw.

If FET is not in close contact with white plate, if there is a gap there, heat can not be dissipated and FET will burn.

If you are using QYT genuine rechargeable lithium battery QB58L, power supply will shut down just before FET burns. However, depending on FET production lot used in the final, FET may burn.

If you are using a battery case, FET will burn because power protection circuit will not work.

2022.12.27 Good news

Latest version QYT-28(CRKITS Japan Version) is screwed.

How to disassembly

Remove the knobs

Since it is hard, insert a flat-blade screwdriver into the gap at the bottom of knob and raise knob using the principle of lever.

*The trick is to slowly raise knob.

If you raise it a little and put it back in the gap at the bottom, knob will not be damaged easily.

Remove washer screw with a radiator penThree locations (BNC, Encoder, Volume).

If you have a special tool, please use it.

*Be careful not to crush the threads.

Remove 2 special screws on aluminum heat sinkUse T9 for wrench size. Keep rubber cap of speaker microphone open.

When you press rubber "OK" button on the operation side, aluminum die-cast body will come out.

Pull volume and encoder shaft diagonally backward by pulling them out of case.

Be careful not to cut two speaker wires.

There is a cable on the case body speaker and PCB board.

Absorb solder from core lead (through hole) of BNC connector

GND terminal can be removed by sucking up solder cleanly or by inserting a flat-blade screwdriver under therminal and lifting it while melting solder.

*When working with a soldering iron, be careful not to damage chip parts and FPC (flexible PCB) of TFT liquid crystal screen.

PCB board can be removed from aluminum body case by removing 8 screws that secure PCB to the aluminum body case. If plastic frame attachment of TFT screen is moved upward (upper knob side), claws will come off from PCB.

*Be sure to reverse procedure when restoring.If you put it in the case without screwing PCB board and aluminum body case, next, it can not be taken out.

This transceiver was turned off while transmitting and has not been turned on since.

I checked FET with a transistor checker.

I found that between each terminal was in resistor condition and the final FET (FQP13N10) was burnt out.

I compared the removed FET to the FET in another transceiver and noticed that the mold shape was different.

Just to be sure, I also removed the driver transistor 2SC2314 and checked it.

This one has short legs, so I extended and soldered the leads.

Checking with a transistor checker, 2SC2314 is alive.

Drill and thread-tap holes in the die-cast aluminum body before installing the new FETs. It is then recommended that the modulation transistor MJE2955T be screw-tapped as well.

It is best to screw both final FET (FQP13N10) and modulation transistor MJE2955T.

If AM modulation is bad, screw MJE2955T to improve it.(See below)

Drain leg of FET is connected to the heat dissipation fin, so when screwing it to die-cast aluminum body, use non-metallic screws or place a plastic collar inside the fin hole to avoid shorting.

You can look two screwed from back side for final FET and modulation transistor.

Pass New FET legs through PCB through-holes.

Always screw the PCB to aluminum die cast body before cutting and soldering FET legs.

Cut the lead out, leaving 1.0 mm to 1.5 mm

Solder FET legs

If modulation transistor MJE2955T is reused, legs are short and lead tips do not protrude much from PCB through-holes. If it is too short, use a new transistor.

After replacing FET with a new one, adjust power.

Max. power (4 W) can be adjusted with power adjustment volume, but even if volume is adjusted, power may not reach 4 W. In such cases, adjust chip resistor (default 150 Ω) near power adjustment volume to raise peak power value.

In such cases, you can increase peak power by adjusting chip resistor (default 150Ω) near power adjustment volume. (+0.5 to 0.8W or so)

In my case, I lowered resistance by soldering a new chip resistor 10Ω over originally attached 150Ω.

For FETs with high Gate input voltage (Vt=4.2V), purchased from Onsemi, it may be necessary to adjust Gate resistor value.

Adjustment example

Original 103(10KΩ) → 8.2K Ω

Original 222(2.2KΩ) → 1.1KΩ

The combination of 7.5KΩ and 1KΩ resulted in 4.6W.

I adjusted it to 4W with power adjustment volume.

I used digital power meter.

I drew circuit diagram of final part from actual transceiver.

I have seen three different types of FETs used in transceiver repairs so far.

Type 1 : I found it in my prototype transceiver that I purchased last year.

This is working fine.

Type 1 is small gate input capacitance and good for using RF purpose.

Type 2 : I found it in two transceivers when I repaired FET was burnt out.

This type was used when repairing two transceivers whose FETs burned out during transmission and shut down the power supply.

No data about type 2 specification.

Type 3 : I found it in more transceivers.

This type was found when repairing transceivers whose power supply shut down during transmission and other reason repair ones. FET was not burnt out.

Type 3 is large input capacitance.

When I repaired type2 and type 3, I replaced them with new Onsemi FET of same specifications as Type 1 and I performed a screw-fastening procedure.

Type 1 has same specifications as FET purchased from ONSEMI and Type 3 is similar to specifications of FETs purchased from Aliexpress. As for type 2, it was burnt out and its characteristics could not be confirmed.

2. AM modulation problem

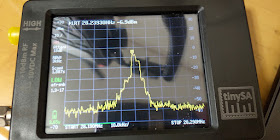

I received a transceiver with dirty AM modulation and bandwidth spreading problems. Observation with a spectrum analyzer showed that it was not over-modulated, but seemed to be self-oscillating.

No modulation, only career signal

At 3KHz sine wave input (I put PC's WaveGene output directly into mic line.)

High input level (over-modulation state)

Bad AM modulation (400Hz sign wave modulation)

Even low level input, still bad modulation

Image of 3KHz sine wave input with no modulation problems

Large input level (3KHz sine wave) with no modulation problems.

Good modulation (400Hz sign wave)

After some experimentation, I have found that three things could be improved so far.

The first was a slight improvement when the shield of the transceiver case was reinforced.

Front panel case has no shielding at all.

I put aluminum tape on the back side of case to give it a little shielding effect.

The second is to attach a GND wire. This is to attach a ground wire to the BNC connector.

The third is to screw in the modulation transistor MJE2955T. This was found to increase modulation and reduce self-oscillation.

Oscilloscope image, AM modulation (1KHz sine wave) before screw MJE2955T.

Oscilloscope image, AM modulation(1KHzsine wave) after screw MJE2955T.

AM peak plus modulation power becomes 10W PEP from 8W PEP after MJE2955T was screwed on the alminum body.

When final FET (FQP13N10) was also screwed in, modulation depth returned to normal sate. But by screwing final FET, modulation was further improved.

FET was replaced from QYT original (high capacitance input) to Onsemi new one (low capacitance input).

This is 400Hz sign wave input result after screwed final FET.

I had QSO with my friend local station and confirmed AM modulation is dramatically improved by screwed modulation transistor MJE2955T.

(Added on 2022.6.26) Owner of transceiver repaired in the past (March 2022) in the power shutdown problem informed me that there is AM modulation problem. Immediately after I received it, I checked and confirmed AM modulation is dirty on the low frequency side of 10m band. In the previous repair, when screwing final FET, modulation transistor MJE2955T was also screwed on, so it was found that additional solution is necessary. In addition, it was found that the recently repaired transceiver also has a phenomenon that the modulation becomes dirty when the external antenna is connected to HB9CV. I will continue to experiment and investigate whether there are any other ways to improve it.

3. Switch problem

If there is a CALL (Err error display), or lamp lights up, or it is difficult to turn on PTT, etc., even though buttons are not touched, check for misalignment of dome switch. Remove transparent tape and correct misalignment.

Corrected misalignment of dome switch

4. Low pass filter measurement

I measured LPF of QYT-28 by Nano VNA.

Masurement was taken without calibrating cables and connectors used, so this is just for reference for now.

Final FET was removed and connected to drain terminal (RFC coil for power supply connected to drain was removed).

Other side is connected to ANT terminal (BNC connector).

There is a current transformer with a ferrite core in the path (directly under the BNC) that is supposed to be used for SWR detection.

I measured again after RFC coil for power supply is connected to drain pad. Then LPF cut off frequency becomes about 50MHz.

5.PLL Unlocking

There was an unlock phenomenon in a specific frequency range of 29MHz.

This was the first time this phenomenon had occurred, but the cause was found immediately after opening the case.

A thin wire in the power supply line?

Oscillation was weakened at the higher frequencies due to voltage drop caused by a thin wire connected to another circuit.

It was removed and stabilized.

6. No sound only in FM modeSignal is received and S-meter shakes, but no audio is heard.

When PCB board was removed from the case, it was found to be warped (left side).

After loosening the screws and correcting the warping, it was fixed. However, after a while after putting it back in the case, it came back. It seems that some component related to FM mode has a bad contact.

I am currently investigating.

Concluding Remarks

If you are an amateur radio technician, you will surely enjoy improving CB-58 (QYT-28) with your ideas and ingenuity.

CB-58 (QYT-28) Handy Transceiver is a nice way to communicate outdoors, under the blue sky !

By JO1ACW

73s

Sleeping =^_^=

Very informative! Very helpful photos too. Do you have any experience to deal with the microphone gain problem for QYT CB-58? I always need to shout at the microphone. Which potentiometers could I adjust to increase the microphone gain? Thanks.

返信削除